Eliminate PCB Spins with SIMPLIS

About one third of power supply PCB iterations are actually addressing more than one design error. To determine the percentage of PCB spins that can be avoided, it is necessary to look at the percentage of ECOs that address only detectable errors.

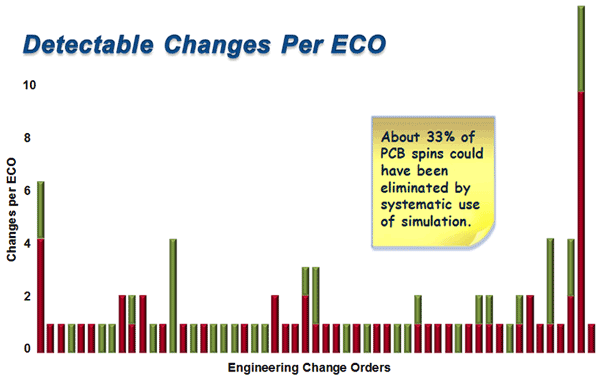

This figure shows only design errors that required a PCB layout change to correct. The errors detectable by simulation are shown in green. An Engineering Change Order (ECO) may contain one or more design errors that require a new PCB layout. In order to avoid a new layout, each one of these design errors in a given ECO must be detected by the testing of the virtual prototype. As these data show, a virtual prototype could have prevented 33% of the PCB layouts based on the detection of 56% of those design errors requiring a new layout.